Heat Recovery Steam Generator Structure and Process

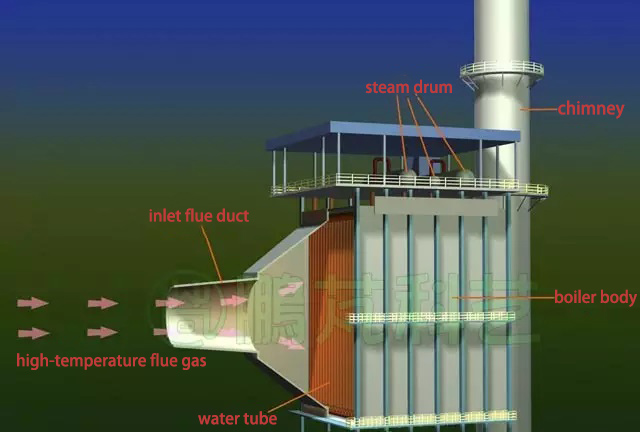

admin2023-03-01T08:06:50+00:00Heat Recovery Steam Generator (HRSG for short) recovers heat from gas turbine waste gas. The flue gas out of gas turbine has a temperature of 600C. These high-temperature gases enter waste heat boiler to heat water into steam to drive steam turbine to generate electricity. The generating capacity and thermal efficiency of combined cycle unit can increase by about 50%. This steam boiler, which generates steam by the waste heat from gas turbine, is Heat Recovery Steam Generator. Heat Recovery Steam Generator mainly consists of inlet flue duct, boiler body, steam drum and chimney.

Heat Recovery Steam Generator Structure

The waste heat boiler body adopts modular structure to facilitate transportation and installation. The module is composed of tube clusters, which is a serpentine tube assembly. Upper and lower header are at both ends of module, and water in the module is heated by high-temperature gas. In order to better transfer heat, fins are welded on outer surface of pipe to increase heat transfer area. Most of the modules are evaporator, economizer and superheater.

Heat Recovery Steam Generator Steam and Water Process

Three-pressure reheat cycle waste heat boiler is common in large-scale gas turbine power plant. The steam-water system includes three parts: low pressure, medium pressure and high pressure part. It can generate low-pressure, medium-pressure and high-pressure superheated steam at the same time.

The low-pressure part consists of low-pressure economizer, low-pressure steam drum, low-pressure evaporator and low-pressure superheater. Cold water from condensate pump is preheated by low-pressure economizer and then input into low-pressure drum. The water is heated into saturated steam in the low-pressure evaporator and rises to low-pressure drum. Saturated steam is output from low-pressure steam drum and heated by low-pressure superheater to generate low-pressure superheated steam.

The medium pressure part consists of medium-pressure economizer, medium-pressure drum, medium-pressure evaporator, medium-pressure superheater and reheater. The water from low-pressure drum is injected into medium-pressure economizer for further heating. It is heated into saturated steam in the medium-pressure evaporator and rises to medium-pressure drum. Saturated steam output from medium-pressure steam drum is heated by medium-pressure superheater, and reheater to generate medium-pressure reheated steam.

The high-pressure part consists of high-pressure economizer, high-pressure steam drum, high-pressure evaporator and high-pressure superheater. The water from low-pressure steam drum is injected into high-pressure economizer for heating. It is heated into saturated steam in high-pressure evaporator and rises to high-pressure steam drum. Saturated steam output from high-pressure steam drum is heated by high-pressure superheater to generate high-pressure superheated steam.